Carbon fibre in car production – weighing up the benefits

Until recently, the use of carbon fibre in vehicle manufacture has been confined to high-end, low-volume vehicles - a fashionable choice for the automotive elite. Yet times are changing.

F1 light years ahead

For some time, carbon fibre has been used in F1, aerospace and marine applications and has gradually been making its way into mainstream vehicle manufacture. Although the main applications for carbon fibre in mass produced cars to date include cosmetic enhancements, automakers are considering its use in suspension components and body panels, albeit in measured doses.

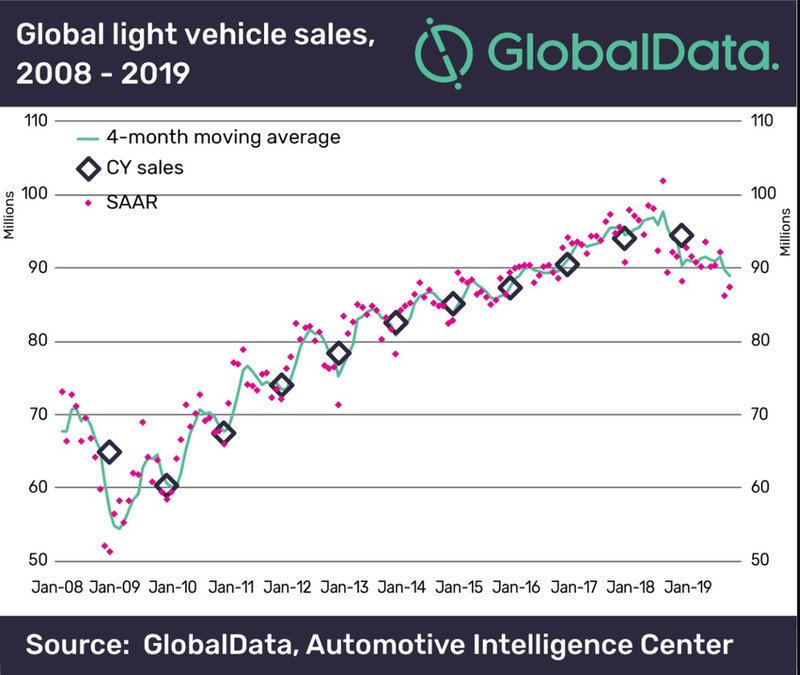

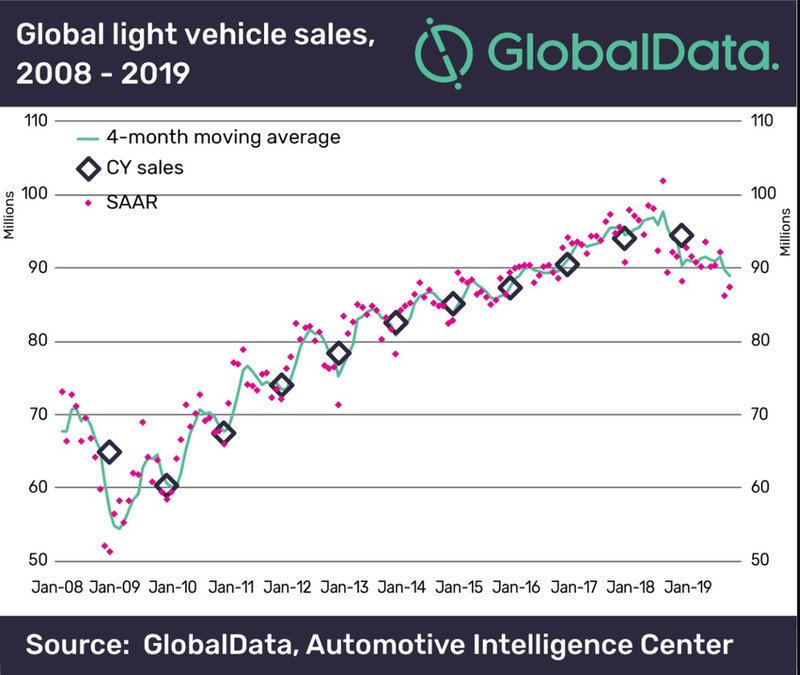

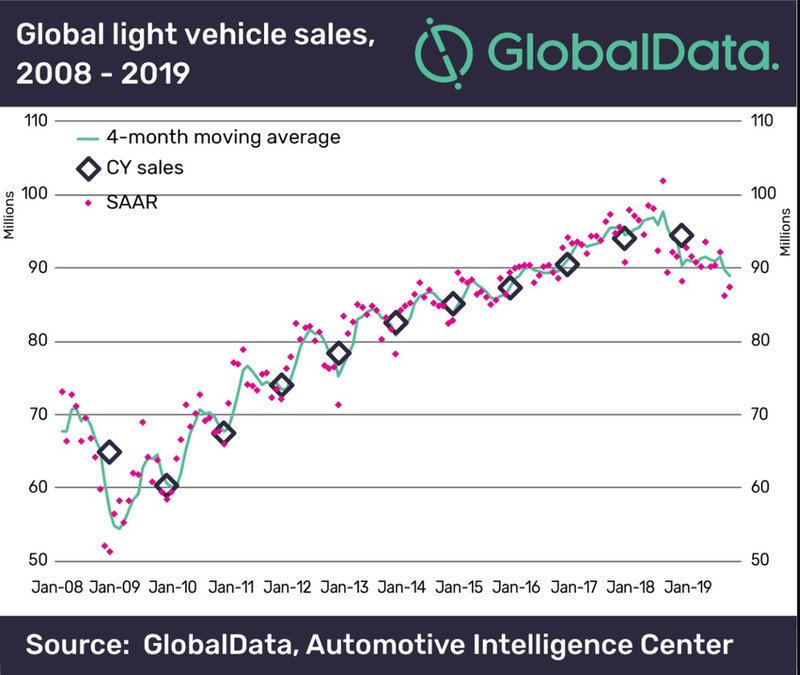

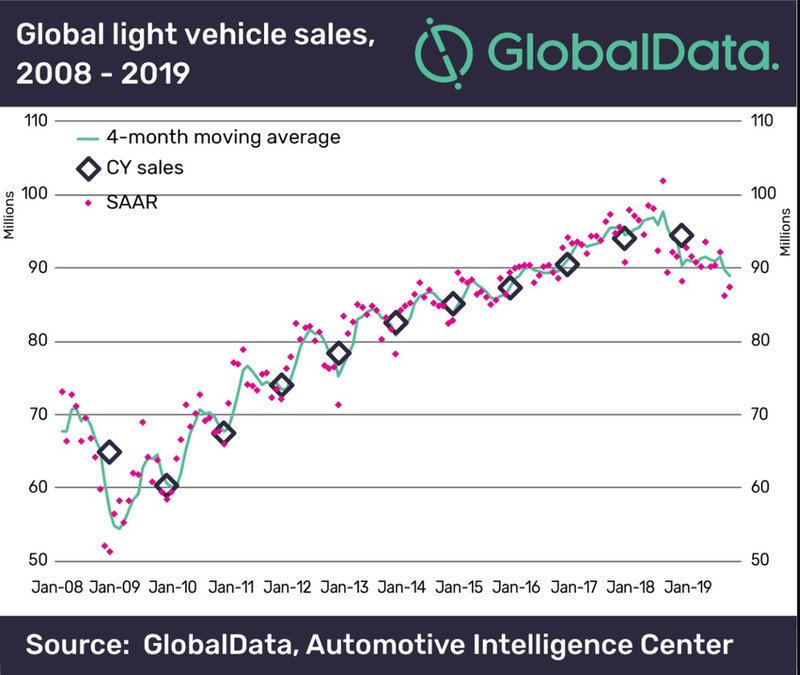

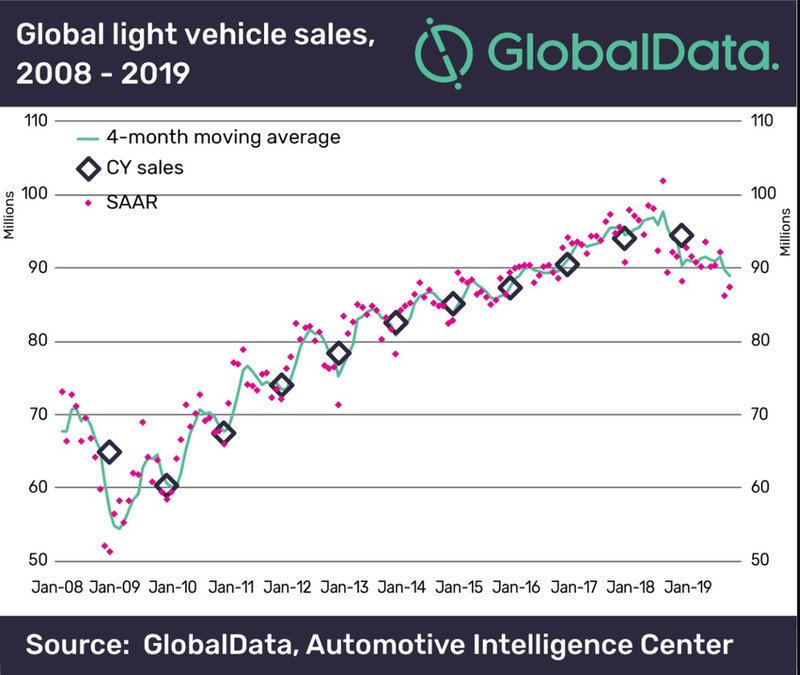

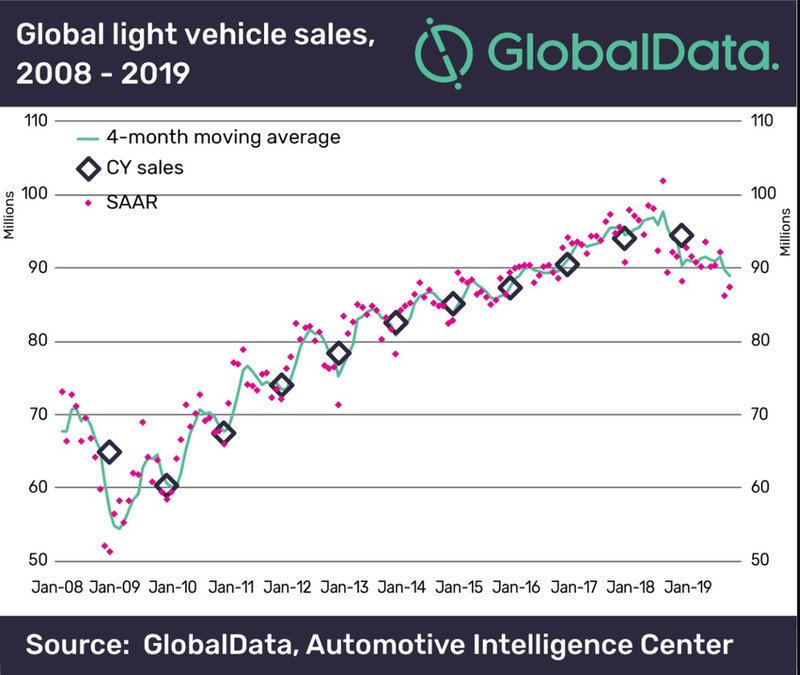

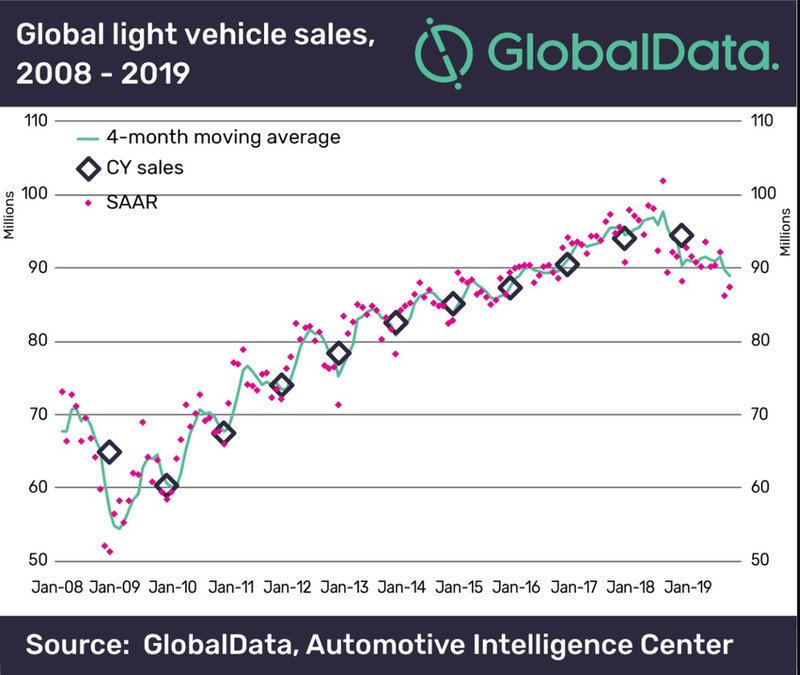

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

McLaren Automotive is using CFRP

Applications of carbon fibre reinforced plastic (CFRP) have been widely used in high-end racings cars. For example, McLaren has pioneered the use of carbon fibre in vehicle production for more than 30 years. The MP4/1 was the first car on the Formula One grid to feature a carbon fibre chassis. Compared to the aluminium structures of the time, carbon fibre was lighter but stronger and therefore faster but safer. McLaren's more recent carbon fibre monocoque cars include the 675LT and 720S.

McLaren Automotive has created a Composites Technology Centre close to the campus of the Advanced Manufacturing Research Centre (AMRC) at the University of Sheffield, UK. The centre will develop and manufacture the Monocell and Monocage carbon fibre chassis for future models. The next generation Monocell will be built using advanced automated manufacturing techniques developed in conjunction with the AMRC.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

Other automakers also adopting CFRP

Other high-end automakers have made liberal use of CFRP parts in their cars in order to shed weight, including the likes of Daimler, BMW (i3 and i8) and Lamborghini (Aventador and Huracán).

Audi, Alfa Romeo and Toyota are also integrating CFRP in certain pockets of their cars. For example, the Toyota Prius PHV is claimed to be the world's first mass-produced car fitted with a CFRP tailgate, another weight reduction measure.

As demand for the material has risen, the appetite for custom and novel finishes has soared. The concept of 'mass customisation' is one that is increasingly on the agenda of OEMs. Recent investments in JLR's SVO department, Aston Martin's 'Q' and Ferrari's 'Tailor Made' are examples of how automakers are responding to the often more nimble tuning and customisers that have risen in prominence. Alongside performance engine enhancements and bespoke interiors, one material that has seen a rise in consumption is carbon fibre. From 'hot hatches' through to luxury limousines and SUVs, this composite material is no longer purely reserved for motorsport specials. For luxury cars, it is almost a commodity.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

Supported by their suppliers

Ford is also taking a closer look at CFRP, supported by Magna. The pair have developed a prototype carbon fibre composite subframe claimed to reduce mass by 34 per cent compared to a stamped steel equivalent. By replacing 45 steel parts with two moulded and four metallic parts, the prototype achieved an 87 per cent reduction in the number of parts. The mouldings are joined by adhesive bonding and structural rivets.

Joe Laux, Magna Exteriors director advanced engineering, told just-auto why demand from OEMs for the lightweight material is now growing: "Carbon fibre use continues to grow very rapidly for a number of reasons (primarily strength versus weight ratio) in multiple industries. The first uses of carbon fibre were materials designed for the aerospace and racing industries. However, these initial offerings were not focused on cycle times because they were designed for low volume applications. For this reason there is a tremendous opportunity to develop materials focused on improved process time and that is where we place considerable focus. This, in combination with improved material costs, will grow the use of carbon fibre applications in the automotive industry."

Faurecia has joined the cluster MAI Carbon of the Incorporated Society of Carbon Composites based in Augsburg, Germany in order to develop manufacturing processes capable of reaching automotive cycle times for mass production of composite parts. Composites certainly support automakers to shed weight. The group believe that using carbon composites provide weight savings of around 50 per cent versus the equivalent part made from steel. Ten kilogrammes of weight savings reduce CO2 emissions by 1g/km. Weight reduction is also important to increase the autonomy of battery electric vehicles.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

Material of choice for concept cars

Carbon fibre has long since been a choice material for concept cars, providing a vision of design freedom and lightweighting. Some, like Hyundai, have received recognition for their innovative carbon-fibre frame designs. Others have taken a clean sheet approach, making extensive use of the material. For example, the Shell Project M car is the result of a technology partnership between Gordon Murray Design, Shell Lubricants and engine specialists Geo Technology. The trio have co-engineered the car's body, engine and lubricants to minimise fuel use and CO2 emissions. It is hoped that by achieving a three-digit mpg number will inspire fresh thinking regarding personal mobility while minimising energy using existing technologies and materials. The car is a reengineered version of Gordon Murray's T25 city car, produced in 2010.

The most notable aspect about Project M's lightweight design is that it combines a low-cost recycled carbon fibre composite body with a steel tubular frame. This part of the car was thanks to Gordon Murray Design's iStream concept that enabled the team to build a car weighing in at 550kg, or about 250kg lighter than a Smart car and 80kg lighter than the original T25. The low-energy iStream manufacturing process uses lightweight materials to cut assembly costs, and reduces the capital investment required to produce a car.

The former McLaren F1 designer, Gordon Murray told just-auto: "This project is based on the T25 – that was our first demonstrator for iStream. It was never meant to be for sale but just a physical entity to showcase what iStream was. And we thought that we would optimise that. Working with Geo Technologies and Shell, I had to push the designers much harder on weight saving and that has actually moved iStream on. We now have Yamaha and TVR using technologies from this car."

Gordon Murray Design is also involved in the Carbon Aluminium Automotive Hybrid Structures (CAAHS) project, a collaborative project that aims to further develop the next generation aluminium alloy materials and processes for application in automotive body structures.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

Gordon Murray Design claims it can halve vehicle body weight

Gordon Murray Design has also unveiled a version of its iStream automotive manufacturing system which it says revolutionises the way cars are manufactured and delivers up to a 50 per cent reduction in body weight.

The system combines a high-strength aluminium frame with advanced carbon fibre composite panels to bring 'Formula One-derived construction and technologies to mainstream car production'.

The company says the new process promises to usher in a new era of vehicle performance with the lightweight structure offering greater safety, lower emissions, improved handling, and enhanced durability. The company claims the new innovation not only delivers up to 50 per cent weight reduction compared with a standard stamped-metal body, it also offers new levels of platform flexibility.

Gordon Murray Design says that the modular nature of the iStream Superlight chassis means the core platform can be adapted to suit every segment of vehicle from sports cars and ultra-efficient electric city cars to SUVs and light commercial vehicles. This adaptable formula ensures, it is claimed, 'cost-effectiveness for manufacturers by avoiding the need for high capital investment and individual chassis designs for each model variant'.

Professor Gordon Murray said: "The new iStream Superlight approach to vehicle manufacturing is a paradigm-shifting innovation for the global automotive industry. It is a breakthrough that will deliver the lightest chassis technology for decades to come. The Gordon Murray Design team has created a unique, adaptable and cost-effective way for manufacturers around the world to dramatically improve vehicle performance and efficiency."

'iStream Superlight' employs a high-strength aluminium thin-wall tubular frame and honeycomb recycled carbon-composite chassis panels in place of the stamped metal used in most volume car production.

The company also says that a low weight aluminium frame can deliver a cost neutral BIW when compared to stamped steel.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

iStream lightweight seat

Gordon Murray Design has also revealed a new seat innovation – the iStream lightweight seat, which uses the same materials, techniques and technologies as the iStream chassis.

This newly-developed seat incorporates glass or recycled carbon-fibre composite and a tubular frame to achieve dramatic weight savings. The company claims that compared to a typical vehicle seat, the iStream lightweight seat achieves a weight reduction of up to 30 per cent. The iStream lightweight seat can be designed to suit all types of passenger vehicle.

While the design is aimed at weight saving in passenger cars, the new seat has the potential to benefit other passenger transportation sectors. From aerospace to rail, the patented design delivers new levels of lightweight and low tooling costs, it is claimed.

As far as 2020 is concerned much depends on prospects for the economy and measures that Beijing may introduce to stimulate demand.

End-of-life challenge

At the other end of the vehicle spectrum, it appears that processes to manufacture carbon fibre have moved faster than those for recycling it. There are still challenges when it comes to end-of-life recycling of carbon fibre parts. Lukas Schröer, project manager of lightweight technologies at Lanxess High Performance Materials business unit, told just-auto: "The availability of recyclable material is still limited to small volumes. Therefore, the establishment of a cost-competitive and sustainable value chain for recycled carbon fibres is still unfeasible from our point of view."

On balance, although carbon fibre has been drawing industry attention as their lightness and strength can help the fuel efficiency of vehicles, the time-consuming work (and cost) required to produce car parts using the material remains a drawback. Despite some significant advances in developing such processes, there are still some challenges that need addressing.

BMW i3 in production

Gesture recognition

Looking down at a touchscreen (without haptic feedback) can be distracting. Gesture recognition is therefore said to be the Next Big Thing, regarded as the logical next step from touchscreens and buttons. Gesture control operates via a stereo camera within the cabin that can recognise certain hand movements for pre-programmed adjustments and functions. Rotating your finger clockwise at a screen could turn up the volume or a finger gesture could answer or decline a call. While such novelties will make life simpler for the driver, it should also simplify interior design and liberate space for storage options.

Interior lighting trends

Advances have also been made in the interior lighting department. Not so long ago, interior lighting consisted of central and side headliner lights, complemented by low-level ambient lighting located mainly in the cockpit area. Today, the accent has changed, thanks to widespread use of LEDs enabling personalisation of car interiors. For example, during night time driving, the Mercedes-Benz E-Class takes on an entirely different feel thanks to the ambient interior LED lighting that can be personalised using a palette of no fewer than 64 colours. It really does start to feel like a cockpit, adding illuminating highlights to the trim, the central display, the front stowage compartment on the centre console, handle recesses, door pockets, front and rear footwells, overhead control panel and mirror triangle.