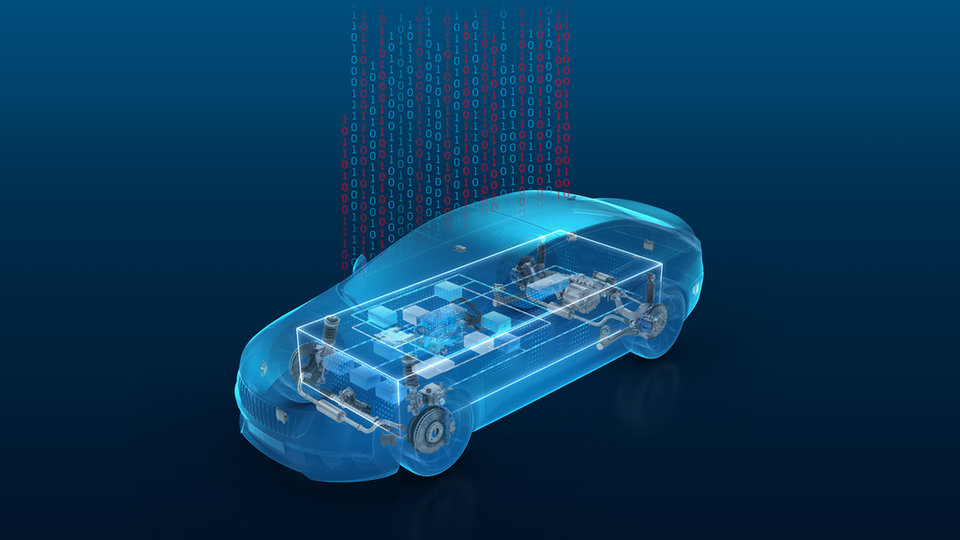

Image: Michele Rinaldi / Shutterstock.com

Image: Michele Rinaldi / Shutterstock.com

ZF on brake controls, steer-by-wire and sourcing chips

For the latest trends in electronic braking and steering systems, we caught up with Rich Wolfe, Executive Vice President, ZF Active Safety Division.

Fabrizio Barcellona, coordinator of the Seafarers and Inland Navigation Section of the International Transport Workers' Federation. Image: Rory McCourt, ITF

Fabrizio Barcellona is coordinator of the Seafarers and Inland Navigation Section of the International Transport Workers' Federation, which he joined in 1993. Previously, he held several positions at the International Transport Workers’ Federation (ITF), including as head of the ‘Actions’ unit and manager of the maritime operations team.

Ukko Metsola, director-general for CLIA in Europe. Image: Charlotte Humphrey, CLIA

Ukko Metsola leads Cruise Lines International Association’s (CLIA) presence in Europe, serving as director-general. Previously, he served as vice president for government relations in Europe and Asia-Pacific at Royal Caribbean Group, and has also held senior positions in the Finnish Parliament and in the Finnish prime minister’s office.

JustAuto: What are the megatrends in the automotive electronic braking system industry and how could that shape the performance of tomorrow’s brakes?

Rich Wolfe (RW): Advancements in vehicle braking systems are primarily being shaped by the industry megatrends of electrification and autonomy. ZF is a world leader in braking systems for both light and commercial vehicles following the acquisition of WABCO last year – for the purposes of this discussion we will concentrate more on the light vehicle market but ZF is now a major player for larger trucks globally for both the base air and hydraulic braking systems and foundation brakes where we see drum brakes being replaced by air disc brakes at a rate of more than 5 percent per year in selected markets. ZF also has an outstanding offering of electronic braking systems supporting applications like automatic emergency braking with our OnGuard suite of collision mitigation products.

On the light vehicle side, the drivers of technology are similar and ZF is at the forefront of developments. Future braking systems must be powertrain independent as they can no longer rely on the vacuum supplied by internal combustion engines and must work with traditional, hybrid or electric powertrain configurations. They must also generate brake pressure very quickly, which is driven by more stringent NCAP Automatic Emergency Braking (AEB) testing protocols for crossing bicycles – and soon powered two-wheelers. Future brake systems must also be adaptable for ADAS and semi-automated to fully autonomous driving capability.

In terms of brake controls, what is ZF offering and what trends are you seeing in the marketplace?

ZF’s Integrated Brake Control (IBC) system is a highly scalable solution and designed to deliver on the megatrend requirements described above. It combines brake actuation and ESC functionality in one unit, has a very fast-acting brushless motor that is powertrain independent and generates brake pressure up to three times faster than previous generation Electronic Stability Control systems. This is ideal for the very fast brake pressure applies that can translate into an up to one G of vehicle deceleration in less than 150 milliseconds for significantly reduced stopping distances. This is highly valuable particularly in crowded urban environments where reaction times are compressed for stopping and provides the best solution to avoid or mitigate accidents with vulnerable road users, such as cyclists and people suddenly crossing roads.

ZF also recently launched its Electronic Brake Boost system (EBB) on Volkswagen’s new electric vehicle generation platform for ID.3 and ID.4 models – it has similar performance characteristics to IBC and is added to an existing ESC to bring additional dynamic performance and reaction times. Both IBC and EBB contribute significantly to C02 reduction through high energy recuperation and enabling automated and autonomous driving capability with redundant control.

In terms of steering systems, we are seeing a push toward fully electric control. Do you see that happening with brakes? What’s your view of the prospects for by-wire wet and dry brake systems?

We expect By-wire Electro-Mechanical braking systems are on the near-term horizon, lagging a bit behind Steer-by-Wire system introduction. ZF sees systems like Integrated Brake Control, which are in themselves a form of wet by-wire technology, as a very effective stepping-stone to full dry by-wire braking technology which will become more prevalent as we reach the end of this decade. We have systems in the pipeline for customers now and plan to be able to deliver full by-wire dry braking systems as the market demands it, however, that it is still some time into the future.

Could you update us on the stage ZF is at with its brake calipers? And EPB technology?

Disc brake systems are by far the most dominant brake systems for light vehicles and ZF produces cast iron and aluminium front, rear and EPB calipers and we are constantly improving designs with the goal of zero drag for fuel economy and minimizing noise, vibration and harshness during the life of the vehicle. As with Integrated Brake Control, ZF is the world volume leader in brake caliper supply – and in fact, ZF’s Collette sliding caliper is the world’s most prolific design with well over 1 billion having been delivered globally. ZF is also the world leader and inventor of the Electric Park Brake motor-on-caliper technology with more than 150 Million units supplied. EPB has become the most preferred rear parking brake solution that brings many benefits versus mechanical park brakes and our offering includes solutions for small vehicles up to light commercial applications including front wheel EPB as well.

Environmental concerns on brake dust emissions from service brakes are another driver of design consideration for future disc braking systems. ZF is working to minimize brake dust through careful examination of friction materials utilized and additional extensive testing of our braking systems.

Steer-by-wire systems have been talked about for years. What’s your view on its prospects?

For decades the standard answer to the question of when steer-by-wire systems would enter the automotive arena in significant volumes was, “in 10 years’ time”. Today in ZF, we believe that is no longer the case. Starting as early as 2022 we will see OEMs introducing steer-by-wire as both an option and as standard fitment. Starting right now, we believe that we are at the beginning of a journey that will see steer-by-wire enter the mainstream. The value proposition underpinning “by wire” technologies is well known in the industry. What has been the game-changer in recent years has been the focus on AD and highly redundant architectures in traditional steering systems. These factors have combined to significantly reduce the conceptual and technological leap from a high-end EPS to steer-by-wire.

Main image credit: Michele Rinaldi / Shutterstock.com

We are hearing how emergency steering assist systems are an important potential part of future vehicles for avoidance of accidents. What is your view?

At ZF, passive and active safety are fundamental cornerstones of our business and two complete divisions of our organisation are focused on these areas. With the effectiveness of AEB in saving lives and reducing casualties in road traffic accidents proven beyond doubt and now seen by many industry experts as probably the most important development in car safety since the seat belt, we see emergency steering assist systems as a logical next step. In fact, we already offer Emergency Steering Support (ESS) products that work together with the driver by applying an additional steering torque during emergency manoeuvres and assist in stabilizing the vehicle. In the future, we see these technologies developing further, operating with greater degrees of autonomy and integration with other safety functions like AEB.

Main image credit: Michele Rinaldi / Shutterstock.com

Electric power steering systems have evolved through a number of technology generations. What could OEMs expect from the next generation?

Electric Power Steering (EPS) systems have evolved in various guises to become the dominant steering technology in today’s light passenger cars. The next generation of products will extend the application range of EPS technologies through higher power capabilities suitable for vehicles like larger SUVs, pick-up trucks and light commercial vehicles. Drivers of current generation EPS systems will also notice an increasing range of safety and comfort features like Lane Keeping, Traffic Jam Assist and Automated Parking. However, the most revolutionary changes, including orders of magnitude increases in system availability through redundant architectures, Over-the-Air (OTA) updates and advanced Cyber Security features, may barely be evident to the average driver – if at all.

Main image credit: Michele Rinaldi / Shutterstock.com

Do you see any strategic shifts in terms of greater or lesser use of single or dual pinion steering systems?

Within ZF, we do expect to see a noticeable shift in the market share of the various EPS technologies in coming years, with Rack Drive (RD) technologies (including dual pinion and single pinion) gaining ground relative to Column Drive (CD). There are a number of factors at play within the industry that are likely to drive this shift. First of all, the trend to native Electric Vehicle (EV) platforms and elimination of the Internal Combustion Engine (ICE) creates more potential packaging space around the front axle to accommodate RD solutions. At the same time EV platform “skateboard” layouts, with the battery pack placed in the floor pan of the vehicle can elevate the driving position, steepen the angle of the steering column and introduce challenges in controlling both the magnitude and variability in column collapse forces during a crash. In addition, vehicle manufacturers continue to show focus in developing roomy cockpit concepts, especially for higher Automated Driving (AD) vehicles. This together with increasing requirements for column retraction, stowability, and the trend to larger Head-Up Displays (HUDs) all serve to impose further constraints on packaging space in the upper column area required by CD EPS. All that said, in ZF we do expect CD to remain as the dominant EPS technology in terms of global fitment rate for the foreseeable future.

Main image credit: Michele Rinaldi / Shutterstock.com

We understand that ZF is partnering with Mobileye to develop advanced safety systems for future Toyota Motor Corp vehicles. Can you add any more colour to that?

ZF and Mobileye are working with Toyota and will collaborate closely to produce advanced camera technology integrated with ZF radar technology to power key advanced driver assistance platforms in future Toyota vehicles. Mobileye’s EyeQ®4, one of the most advanced application-specific vision computing system-on-a-chip (SoC) currently available, will be combined with ZF’s Gen21 mid-range radar technology, a high-performance 77GHz front radar designed to meet 2022+ Euro NCAP 5-Star Safety Ratings and enable L2/L2+ Automated Driving functions. The combination will precisely interpret the environment around Toyota vehicles. Together, these technologies will help prevent and mitigate collisions while yielding best-in-class lateral and longitudinal vehicle control. This is the first time that ZF and Mobileye will supply advanced driver assist systems to the world’s number one light vehicle producer.

Main image credit: Michele Rinaldi / Shutterstock.com

What is ZF doing to mitigate the semiconductor chip shortage?

To say this has been a challenging situation for ZF and the industry would be a vast understatement but we are dealing with it head-on with our customers and supply chain partners. Earlier in the shortage, we were scouring all opportunities to find chips in the pipeline but that has since been exhausted. Our teams have been working in overdrive mode to keep the supply of our components and systems moving and allow the production of as many vehicles as possible to continue equitably across our customer portfolio. It’s an incredibly complex and dynamic situation that changes virtually every hour and we are making the best of it and hope to see some relief sometime in the remainder of 2021.

INTERVIEW